Conveyor Machine

Contact Us

nzyu@fsszzjx.com

domei@fsszzjx.com

Classification

Keywords

Product Description

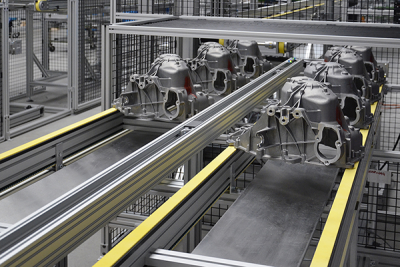

Timing belt conveyors are used to accurately transport products and help provide positive and accurate product placement, they are suitable for light and delicate parts as well as bulky and bulky parts.

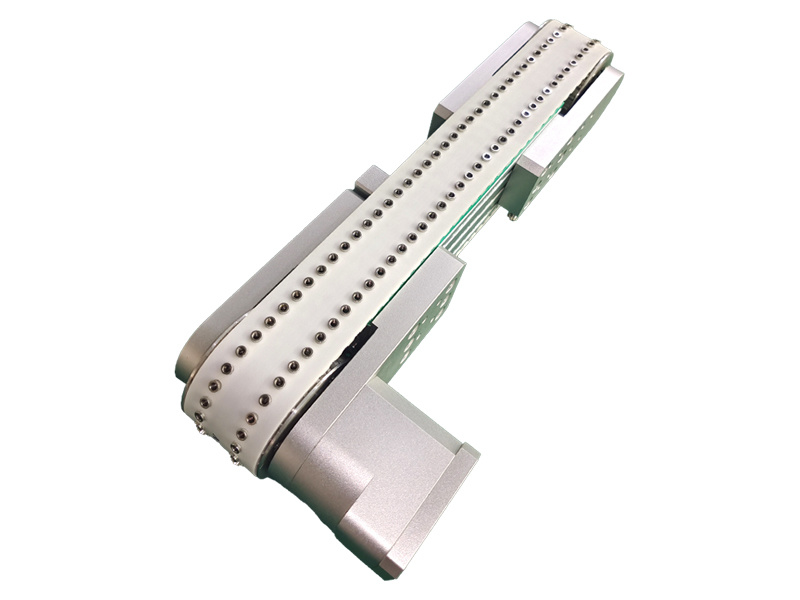

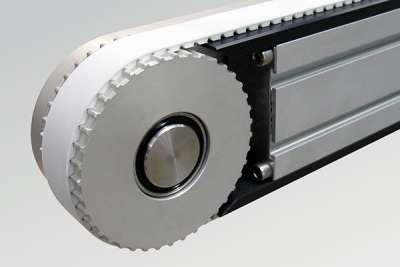

Physically, a timing belt conveyor consists of at least one timing (toothed) pulley and at least one idler pulley (usually another toothed pulley) around which the timing belt wraps.

Timing belt conveyor design

In this conveyor belt cutaway, you can see how the timing belt teeth engage the matching pulleys on the conveyor belt.

The teeth on the timing belt match the teeth on the pulleys. There is a support structure, the conveyor belt frame, that supports the belt and holds the pulleys in place. As well as some sort of device, usually an electric motor, which is used to power the conveyor belt. These conveyors have many typical conveyor accessories such as belt tensioning and tracking devices, conveyor side rails, mounting brackets, and motor controls.

Synchronised belt conveyors differ from other types of conveyors in their ability to accurately convey and position products, especially when used in conjunction with specific belt types, positioning sensors, positioning devices and control systems.

An in-depth look at conveyor timing belts

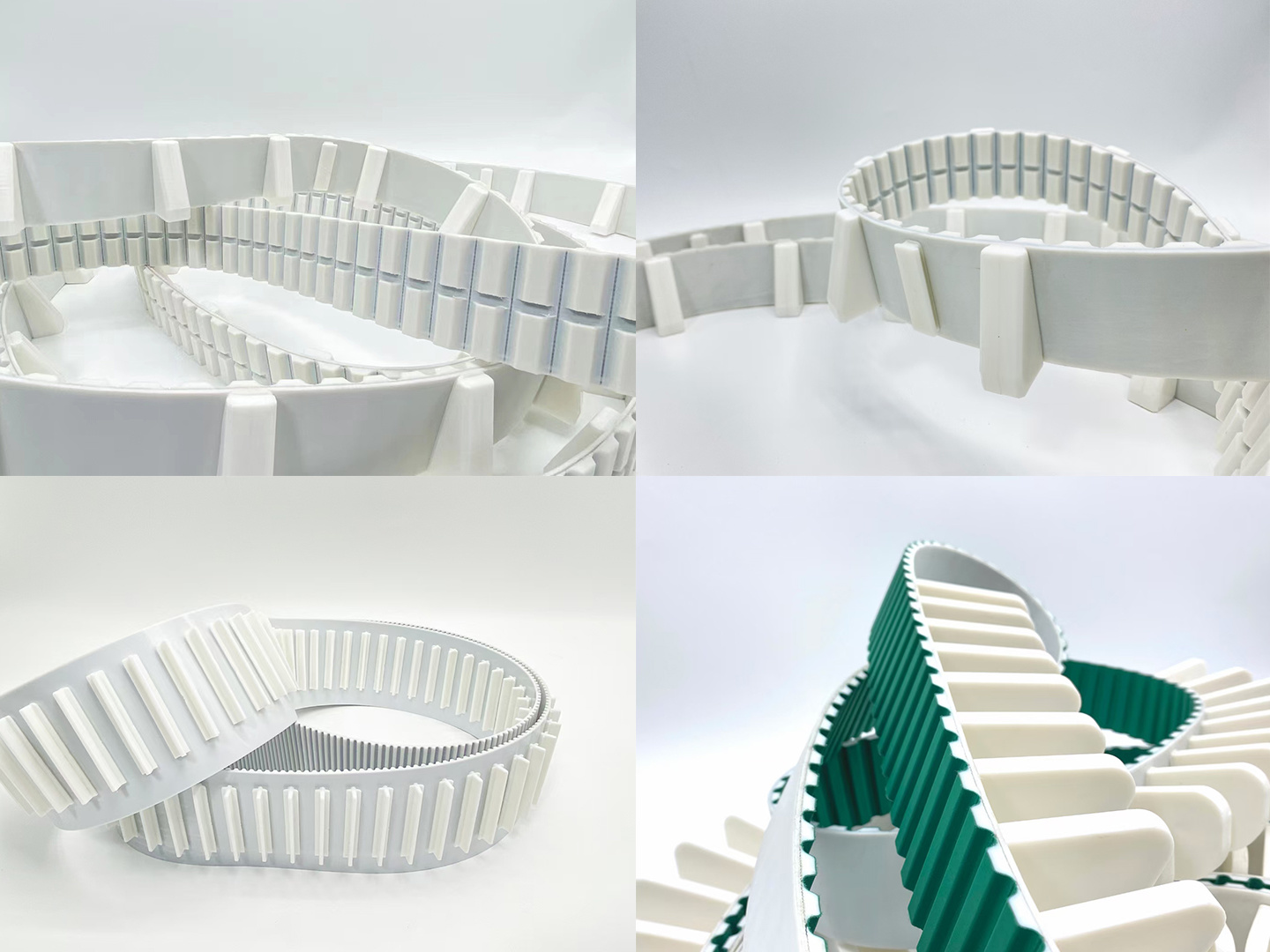

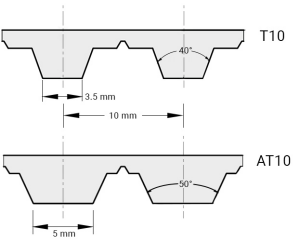

The T10 and AT10 timing belts are both 4.5 mm thick and the teeth are 2.5 mm thick

Timing belts are available in a variety of series and pitches. Pitch is the distance between teeth from tooth centre to tooth centre. Series refers to the style or profile of the teeth and provides an additional method of categorising the belt. Timing belt teeth can be round or trapezoidal, both of which may also vary by series. See the example below showing a T10 timing belt and an AT10 timing belt - both with a 10mm pitch.

The strength of the timing belt is achieved by tension members located in the middle of the belt. These tension members can be aramid or steel. Timing belts requiring FDA approval may have stainless steel tension members.

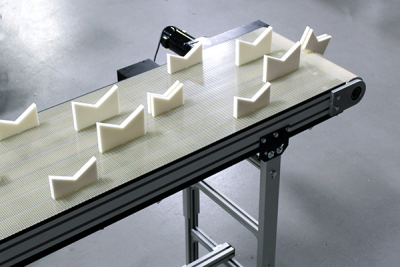

These timing belts have a layer of yellow foam on the top surface.

The tooth side of the timing belt can be coated with a special coating to extend belt life and reduce friction. The top surface of the timing belts can also come in a variety of options - from nylon coatings (for product build-up) to various densities of foam to highly conductive materials.

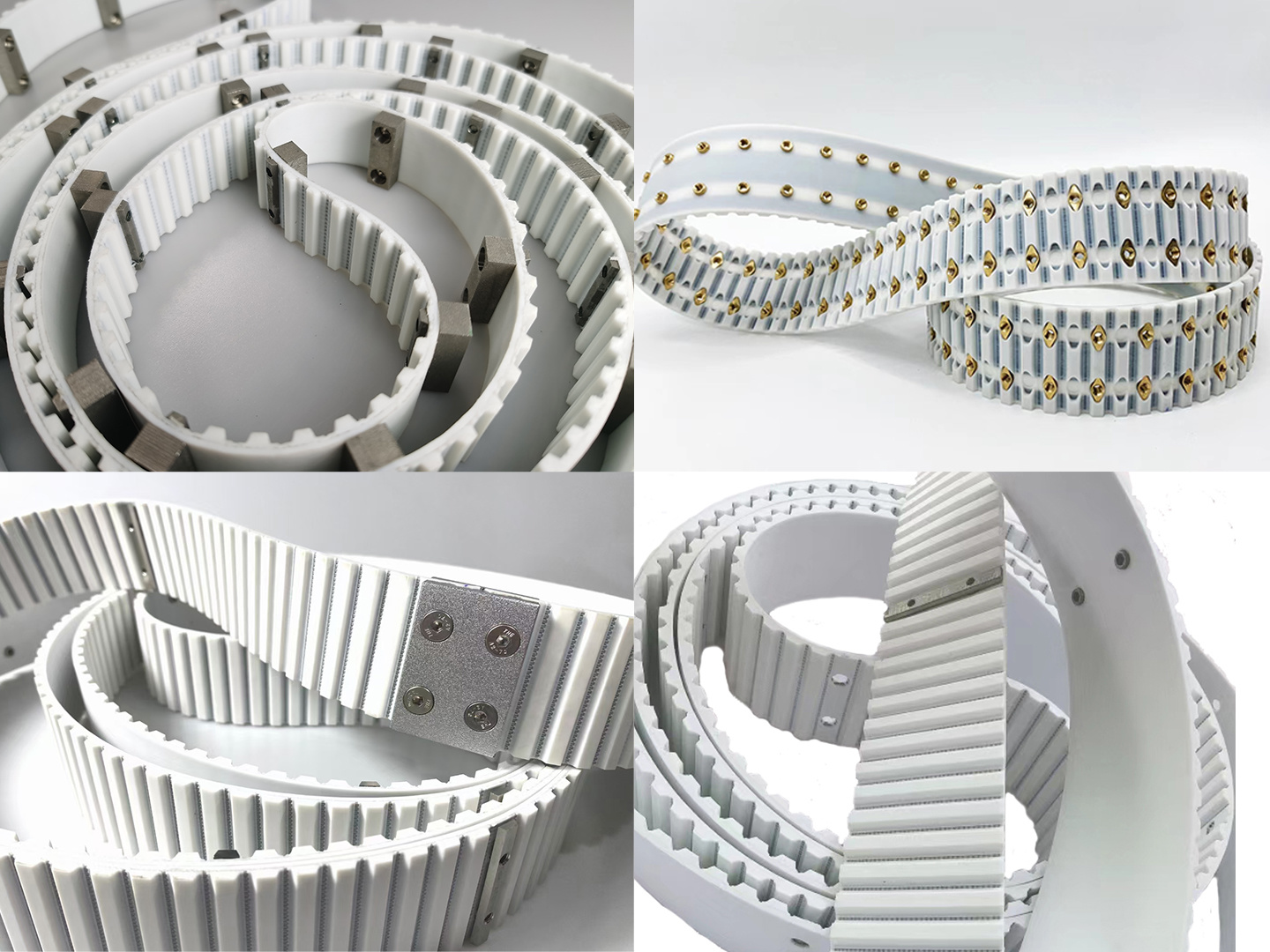

Wide timing belt conveyor with welded custom belt attachments.

Cleats and attachments add to the versatility of timing belts. Various timing belt manufacturers offer standard pre-engineered cleats that can be ultrasonically welded to the belt. In addition, some manufacturers offer custom cleats and attachments that can be designed and welded to the belt.

However, welding cleats to the belt can greatly affect the design of the conveyor because the thickness of the cleats affects the diameter of the pulleys. The thicker the cleat at the vase, the larger the pulley needed. This can be avoided when using a convertible timing belt. This type of timing belt has a pocket in the belt teeth where a threaded insert is placed. This allows attachments to be screwed into this insert. This type of belt has many advantages, for example:

- If an attachment is damaged, it is possible to replace just the attachment, not the entire belt.

- Ability to change the shape of the attachment as product needs change.

- To some extent, it is possible to change the spacing of attachments on the belt.

Precision Indexing Conveyor System

Different types of belts will provide different levels of accuracy. In addition, the choice of motor will have a large impact on the accuracy of the conveyor system. In many cases, the use of stepper or servo motors may be preferable to the use of standard industrial motors. Controllers can be added to the conveyor package and used with the selected motor to create specific motion patterns; this is ideal for indexing and stepping applications. In applications where the highest degree of product positioning and accuracy is required, it is preferable to position the product between cleats on the belt or within fixtures, although these attachments do introduce new tolerances. It is possible to visually position the product or the cleats using a photoelectric eye and, for even greater accuracy, the product can be positively positioned by means of a locating or centring device. These devices are usually pneumatic, but motorised modules are becoming increasingly popular.

Factory Advantages

Foshan Zhizhen Machinery Parts Co., Ltd., established in 2022, the company specializes in the production and sales of perforated conveyor belts, metal conveyor belts, polyurethane timing belts, conveyors, and timing pulleys.

We specialize in the manufacturing and export of porous conveyor belts, metal conveyor belts, polyurethane synchronous belts, conveyors, and synchronous pulleys.

The company implements rigorous quality testing to ensure the excellence of every batch.

We have high-quality factories and strong R&D teams working for customers with bulk order production and efficient, diverse customized request services.

We offer diverse transportation options, such as air or sea, and are committed to delivering exceptional customer service.

PREVIOUS:

NEXT: